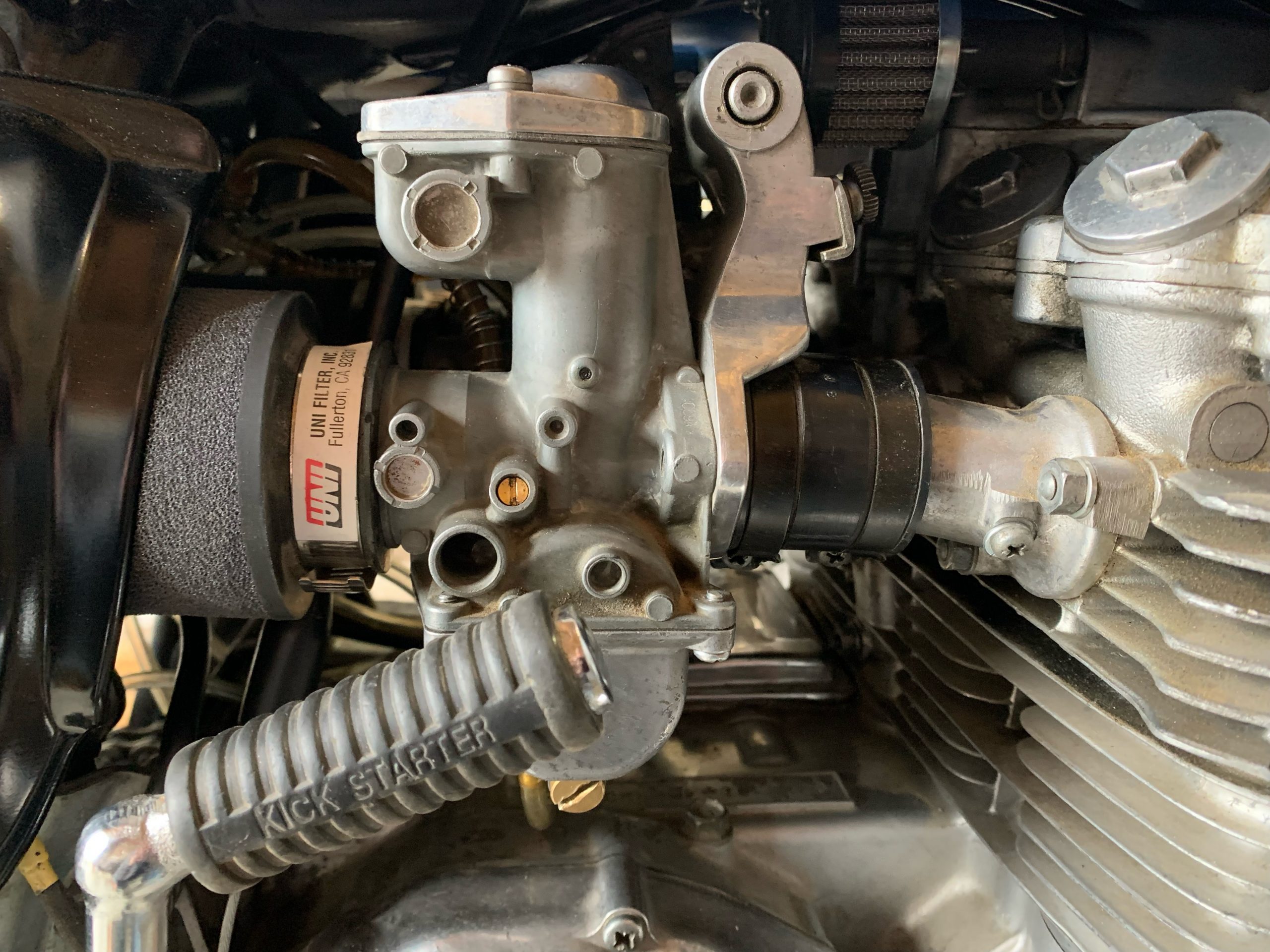

Here’s how I tuned my 1974 Honda CB550 motorcycle with pods.

My bike came with pods when I purchased it. I will share the full story in another post for those who are interested. And here’s the post on the build. But in short, the choke didn’t work. The carburetor was a mess. One of the carb cylinders was bent and jammed with a missing needle. Some cylinders were beyond repair. Glue was in the carbs. And it was leaking fuel. If I can make this bike run well with pods, anyone can make their bike run nice.

Step 1: Clean and rebuild the carbs.

I disassembled and cleaned every nook and cranny of the carbs. It’s an easier job than you may expect. I had 4 sets of containers. 1 for each carb. And took notes and photos as I went. And noted the number of turns each screw was set to. Which made it very easy to reassemble everything.

Step 2. New spark plugs

Step 3: Tension cam chain

Step 4: Set valve clearance

Step 5: Set timing

Step 6: Vacuum sync carbs

When that is done. You are ready to tune the carbs for your pods.

Here’s the settings that are working for me

Set the carb bowl float heights to the stock 22mm

Size 115 main jets. For reference, I live at 1150ft elevation.

Size 42 slow jets (pilot jet)

Raise the sliding needle by moving the clip to the second lowest position. (Opens the needle)

Fuel/air mixture screw is set at 3/4 turns out. Stock is 2 turns out.

Here’s the settings explained

I set the carb bowl float height to the stock height to stop fuel overflowing. And to get a baseline across all carbs.

The main jets effects the amount of fuel you have at the top end. It was running lean. So upping to 115 solved that.

The slow jets effects the low end and idle. If it’s too rich at the low end you need a smaller slow jet. And vice versa.

The sliding needle effects the middle range of power. The more raised the needle the more fuel is being pulled from the main jet in the carbs. I have 4 into 1 pipes with a small muffler. Which increases the air flow. (Again it’s what the bike came with). By raising the needle the bike gets a richer mixture. Solving the “bog” feeling (too lean) when opening the throttle. If you’re sputtering and sluggish when opening the throttle (meaning too rich), then you will want to lower the needle. Another way of checking. If you hold your throttle at mid point and revs climb and run away, that’s lean. If your revs dip or sputter, that’s lean.

The fuel/air mixture screw was the final adjustment I needed to do. It fine tunes the throttle responsiveness and the idle on the low end. To find the setting that is right for you, warm up the engine, then give a bit of throttle and let the revs settle down. Adjust the screws 1/4 turn at a time. Turning the screw clockwise (inwards) enriches the mixture. Outwards leans the mixture. Blip the throttle and let the revs settle down after each adjustment. If it takes too long to settle down to idle then it’s too lean. If you hear backfiring then it’s too lean. If it sputters with throttle or dips below ideal idling (or just die) when settling down, then it’s too rich. Make adjustments to the screws accordingly. When you get the sound you’re happy with (Not lean, not too rich) that’s your spot. Make a note of how many turns you’ve set it to, so you can remember later.

Troubleshooting

If bike is running too lean/rich at idle to 15% throttle? It’s your pilot jet.

If bike is running too lean/rich at the top end? Hearing tinging, clanging, or overheating at full throttle? It’s your main jet.

If bike is sputtering/dying or bogging when giving a little throttle (20-70% throttle). It’s your main needle height.

If bike is backfiring. Adjust your fuel mixture screw.

Final note. Always err on the side of being too rich. A lean condition can be the kiss of death for a motor.

Thanks for checking this out. It’s been an enjoyable and rewarding project.